A hydraulicgenerator is a generator that uses a water turbine as the prime mover to convert water energy into electrical energy. When water flows through the water turbine, it converts the hydraulic energy into mechanical energy. The turbine shaft then drives the rotor of the generator, converting the mechanical energy into electrical energy and outputting it. Hydroelectric generators are the primary power equipment for producing electrical energy in hydroelectric power stations.

The rotational speed of a hydroelectric generator determines the frequency of the generated alternating current (AC). To ensure the stability of this frequency, the rotational speed of the rotor must be kept constant. To stabilize the speed, a closed-loop control system can be used to control the speed of the prime mover (the water turbine). This involves sampling the frequency of the generated AC and feeding it back to the control system that adjusts the angle of the guide vanes of the water turbine, thereby controlling the turbine's output power. Through this feedback control principle, the generator's speed can be stabilized.

Hydroelectric generators can be classified into vertical and horizontal types based on the position of the shaft. Large and medium-sized units generally use a vertical arrangement, while horizontal arrangements are typically used for small units and tubular turbine units.

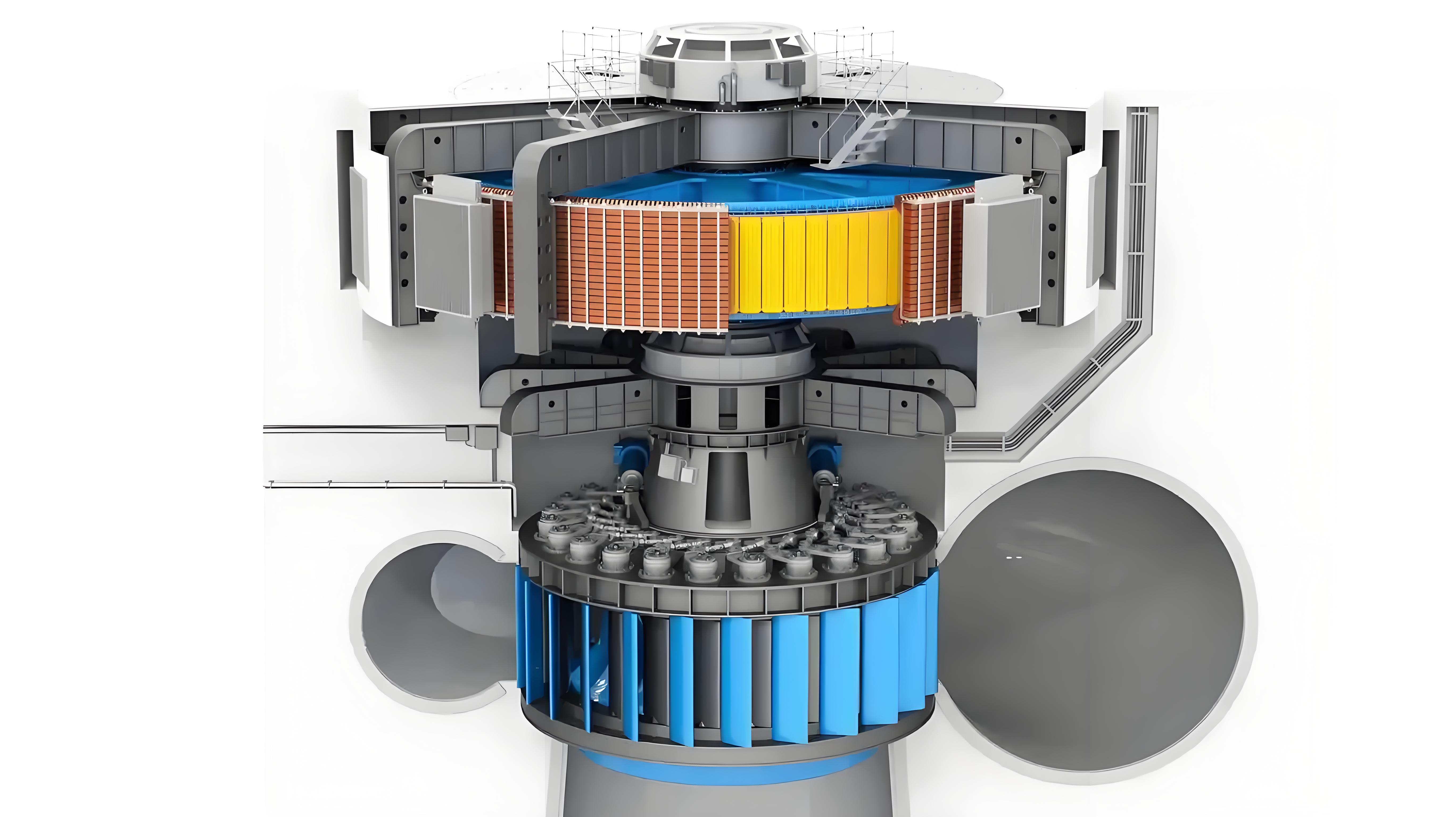

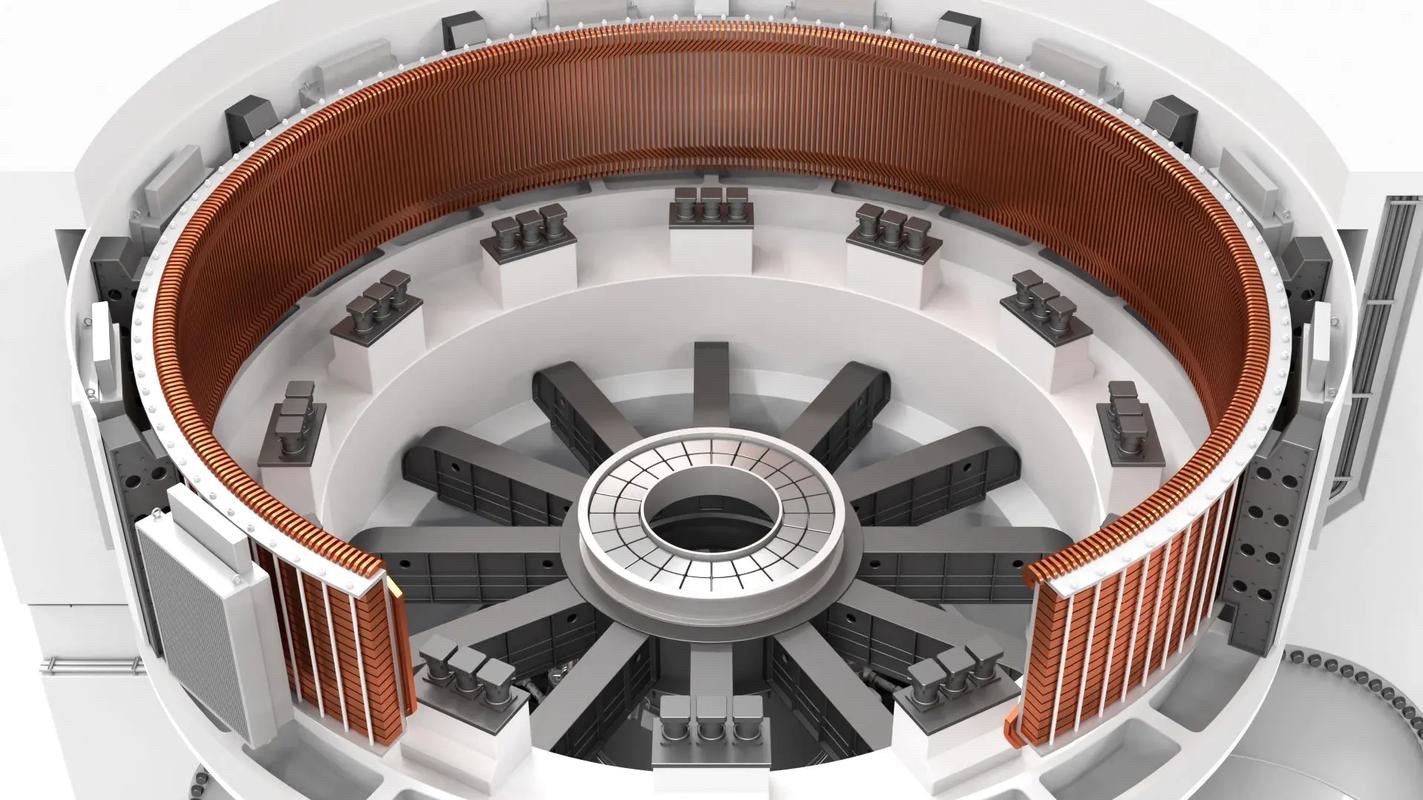

A hydroelectric generator consists of several main components, including the rotor, stator, frame, thrust bearings, guide bearings, cooler, and brake. The stator is primarily made up of the frame, core, and windings. The stator core is formed by stacking cold-rolled silicon steel sheets and can be designed as a single piece or in segments depending on manufacturing and transportation conditions. The cooling method for hydroelectric generators typically uses closed-loop air cooling. For units with very high capacity, water is often used as the cooling medium to directly cool the stator.

The installation structure of a hydroelectric generator is usually determined by the type of water turbine. The main types of structures are as follows:

Horizontal Structure: Hydroelectric generators with a horizontal structure are typically driven by impulse turbines. Horizontal hydroelectric units usually use two or three bearings. A structure with two bearings has a shorter axial length, a compact design, and is convenient for installation and adjustment. However, if the critical speed of the shaft cannot meet the requirements or if the bearing load is too high, a three-bearing structure is needed. Most horizontal hydroelectric units are medium and small-sized.

Vertical Structure: Hydroelectric units widely use a vertical structure. Vertical hydroelectric units are usually driven by Francis or Kaplan turbines. Vertical structures can be further divided into suspended and umbrella types. Generators with the thrust bearing located above the rotor are called suspended types, while those with the thrust bearing located below the rotor are called umbrella types.

Bulb Structure:Bulb generators units are driven by Bulb turbines. A Bulb turbine is a special type of Kaplan turbine with fixed or adjustable runner blades. Its main characteristic is that the axis of the runner is arranged horizontally or at an angle, aligned with the direction of water flow in the intake and discharge conduit.